Part 3 – Balancing Thermal Performance and Durability in Building Envelopes

Part 3 – Balancing Thermal Performance and Durability in Building Envelopes

This post was co-authored by Lauren Gunther (DiMella Shaffer) and Andrea Sonan (BET).

As Massachusetts adopts increasingly stringent energy codes, designers face a critical challenge: how to balance thermal performance, cost, durability, and occupant comfort.

A building envelope—walls, windows, roofs, and foundations—does more than keep the weather out. It drives energy efficiency, impacts resilience, and influences long-term maintenance. Evaluating the thermal performance starts early in design with a holistic approach and careful attention to:

- U-value calculations for walls

- Hygrothermal analysis

- Thermal bridge analysis

- Window performance

Let’s explore why each matter and how they work together.

What Are R- and U-values—and Why Do They Matter?

The U-value measures how much heat escapes through the envelope assembly. Lower U-values mean lower heat transfer and better-performing envelopes. While R-values tell you how much heat is resisted, U-values (the inverse of R or 1/R) give the full picture of heat transfer.

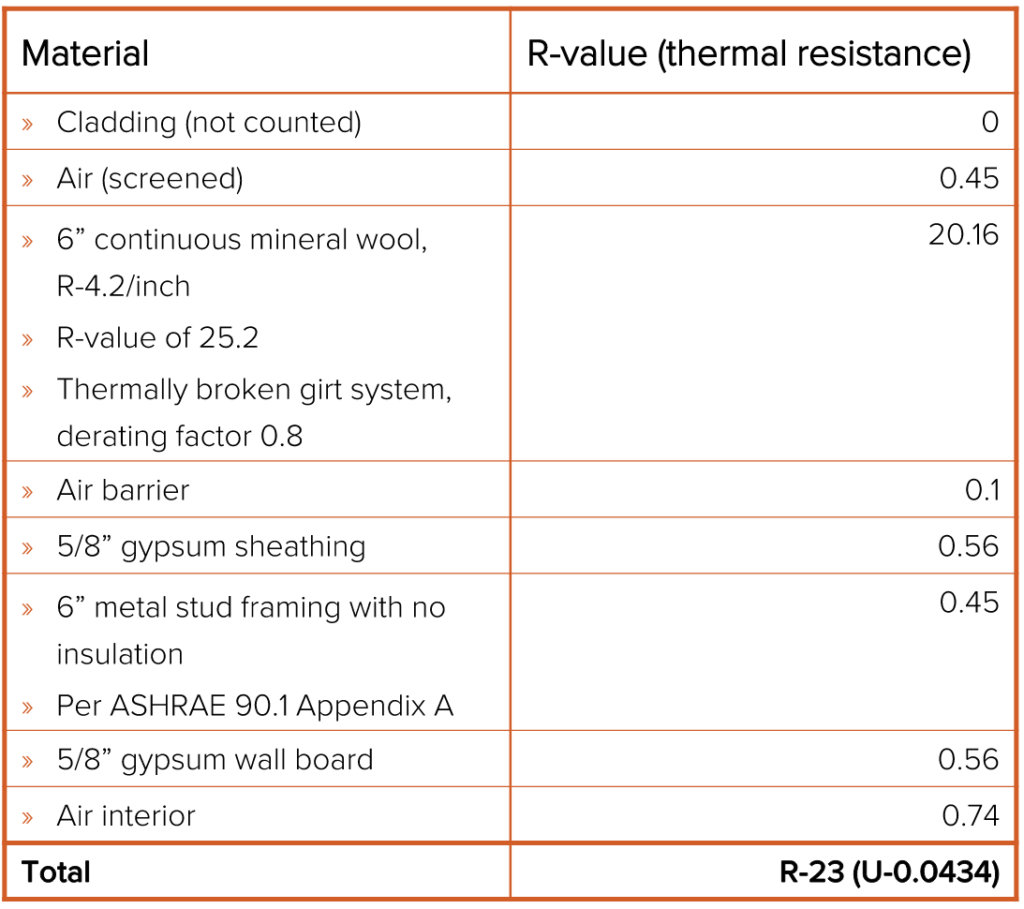

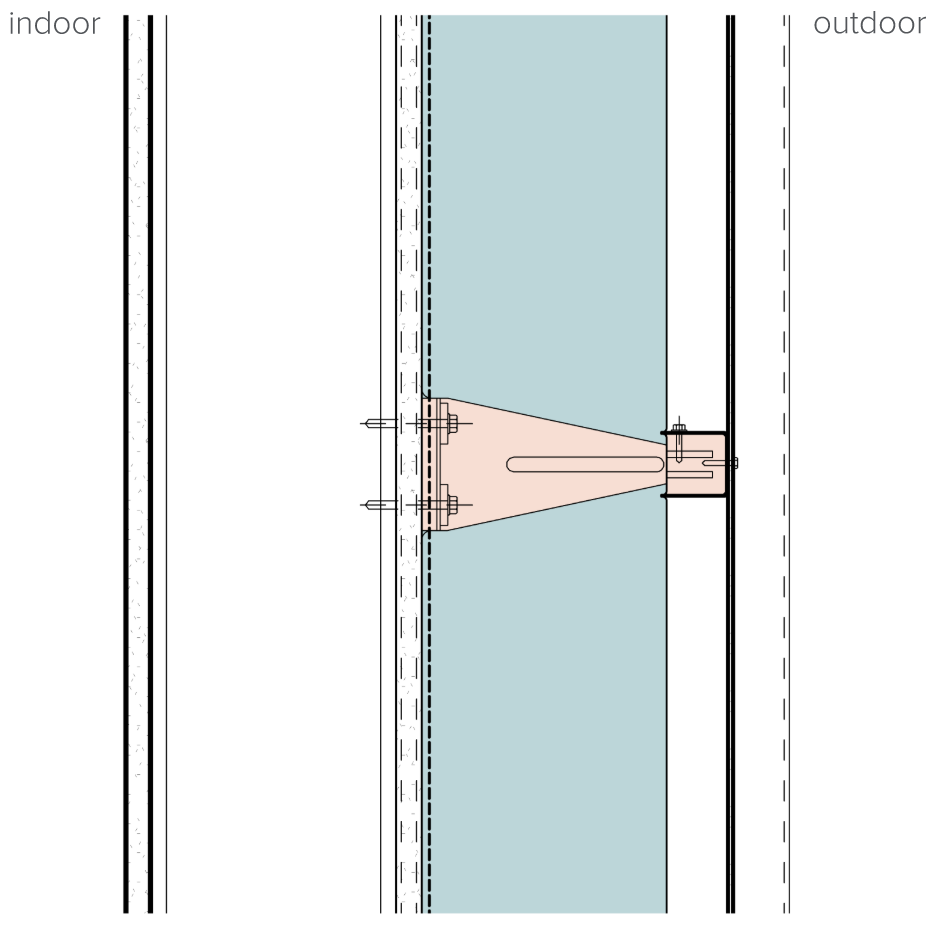

Insulation alone doesn’t determine performance. The structure matters too. When calculating a wall’s initial U-value, we account for uniformly distributed interruptions like studs and cladding attachments. These clear field thermal bridges, explained further below, reduce insulation effectiveness and are factored into the initial R- and U-value below.

Why Moisture Matters: Hygrothermal Analysis

Heat and moisture both move through walls and managing them together is critical. A hygrothermal analysis, often performed with WUFI PRO, evaluates how heat and moisture interact within assemblies. This is especially important when insulation is placed inside the wall cavity. If the dew point shifts into a sensitive layer, there is potential risk of condensation inside the wall, leading to long-term durability issues.

In our example below, only continuous exterior insulation (solid blue) was used, which kept the dew point outside the stud cavity and exterior sheathing. Therefore, a WUFI analysis wasn’t needed.

Thermal Bridges: Big Impact in the Details

A thermal bridge is any break in the insulation layer that allows heat to bypass the insulation. These weak points can cause:

- Localized heat loss

- Reduced energy efficiency

- Moisture and durability issues

Types of Thermal Bridges:

- Clear Field Thermal Bridges – Occur uniformly across the wall, such as studs, girts, and brick ties.

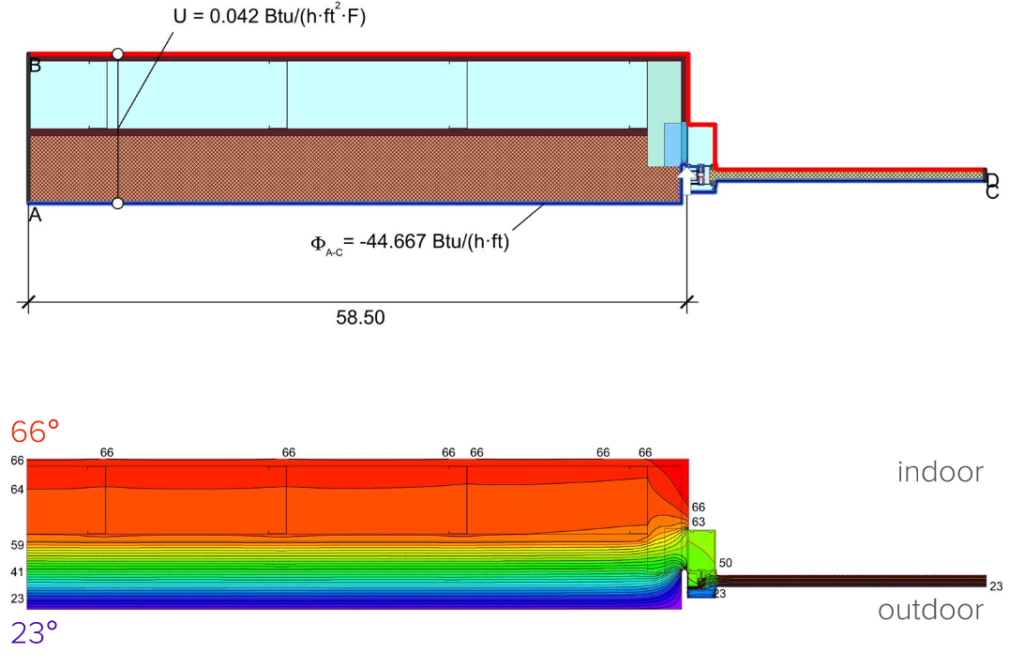

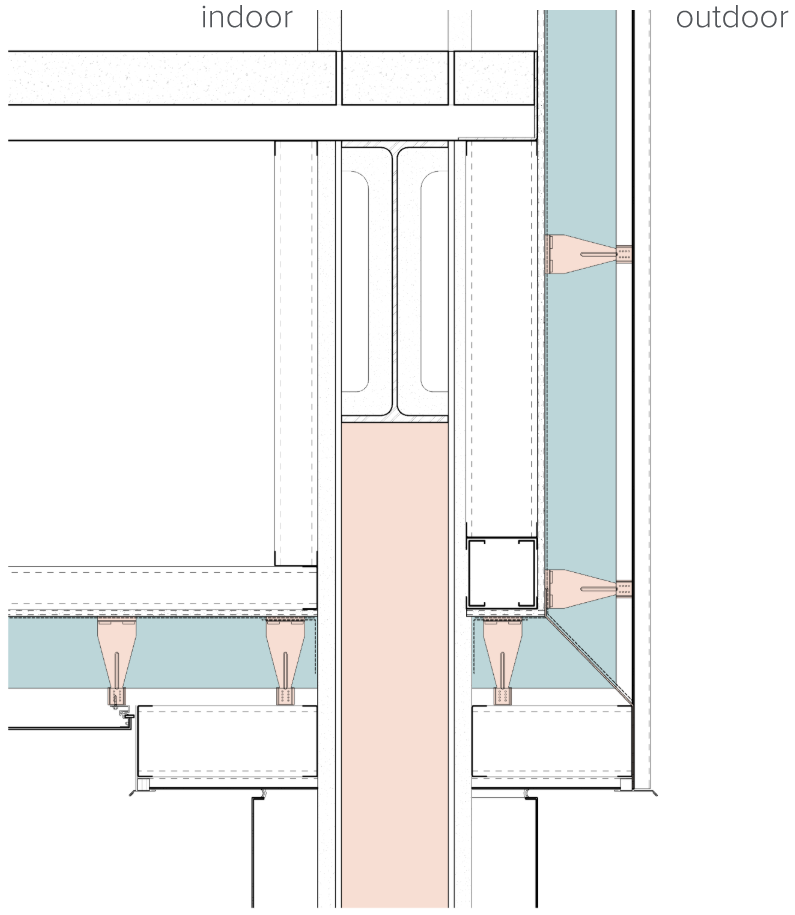

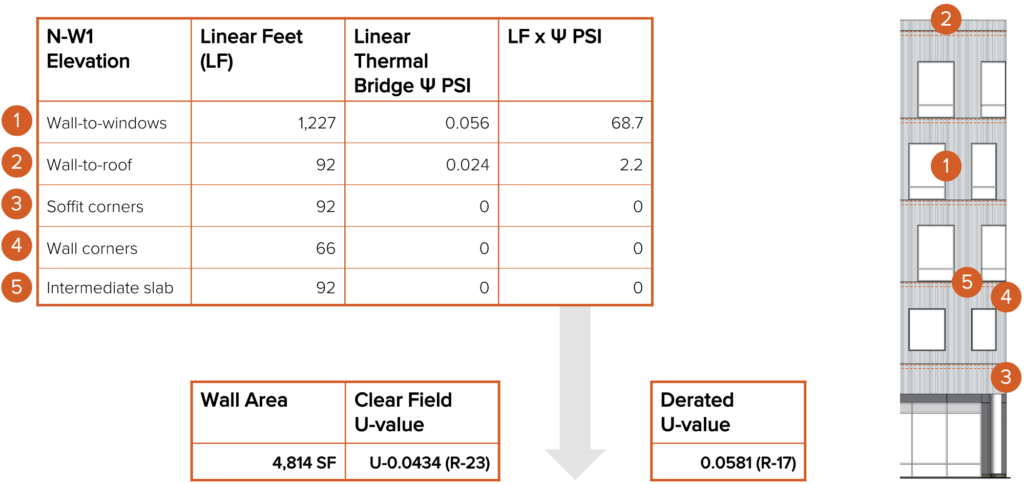

- Linear Thermal Bridges – Found at transitions like wall-to-roof intersections, corners, and wall-to-window intersections. Windows are especially impactful due to their long edges and quantity.

- Point Thermal Bridges – Localized penetrations, such as steel supports for canopies or column penetrations through an exterior soffit as shown below—small in area but significant in impact.

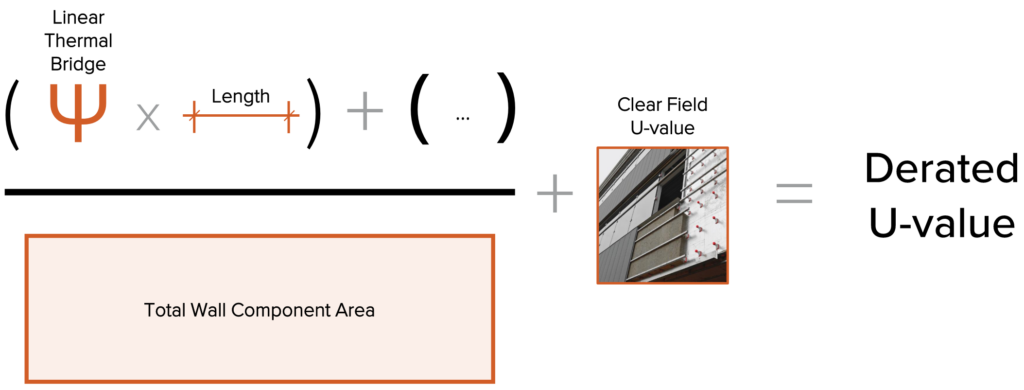

Each thermal bridge type can increase the overall U-value and reduce the performance of the envelope. Identifying and mitigating them early is essential. A calculation and table below can show how much these bridges “derate” the initial performance.

Windows: The Heavy Hitters

Windows typically lose more heat than walls, making their performance critical. It’s not just about the glass—the frame and installation details matter too. A window’s U-value includes both the insulating glass unit (IGU) and the thermally broken frame. Even high-performance glazing can fall short if the frame conducts too much heat or if installation compromises the seal.

Putting It All Together: The Backstop Calculation

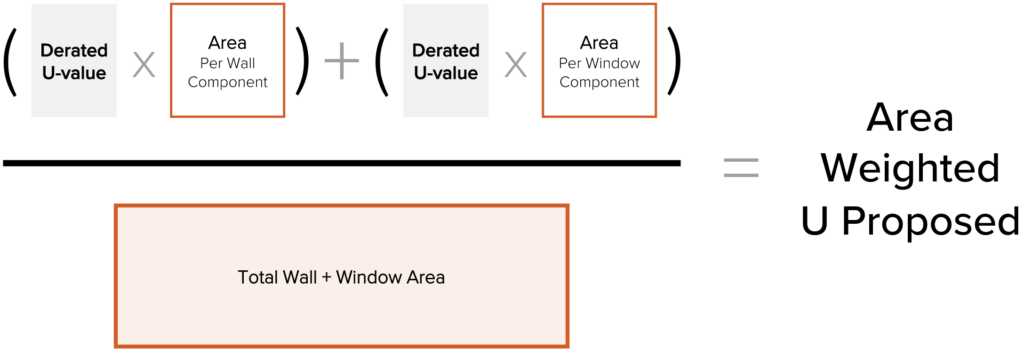

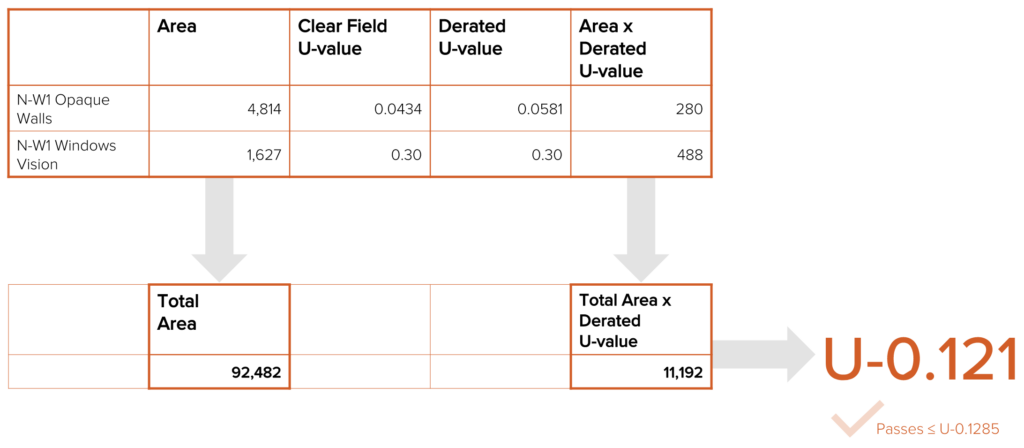

To determine if an envelope meets code, we use the backstop calculation when required by the compliance pathway. This is an area-weighted U-value of all above-grade vertical envelope components, such as walls, windows, and spandrels.

Here’s how it works:

- Multiply the derated U-value of each component by its surface area.

- Add those values together.

- Divide by the total above-grade vertical envelope area.

The result is the envelope’s overall U-value, which must be below the maximum allowed by the Massachusetts energy code. The limit varies depending on the glazed wall percentage (“low glazed” or “high glazed”) and whether it’s new construction or a renovation.

Key Tips for Better Envelopes

- Start the thermal analysis early in design.

- Use continuous exterior insulation to improve the thermal performance of the wall system and to minimize condensation risk.

- Evaluate window frames as carefully as glazing.

- Address thermal bridges at transitions and penetrations, especially at wall-to-window intersections.

By integrating these strategies, designers can create envelopes that meet energy targets while balancing durability, cost, and comfort.

This final installment of the envelope performance series, launched in 2025 and inspired by the Wagdy Anis Symposium presentation developed by Lauren Gunther and Steven McCormack (DiMella Shaffer) together with Andrea Sonan and Lance Robson (BET), builds on the collaborative work that shaped the foundation of the series.